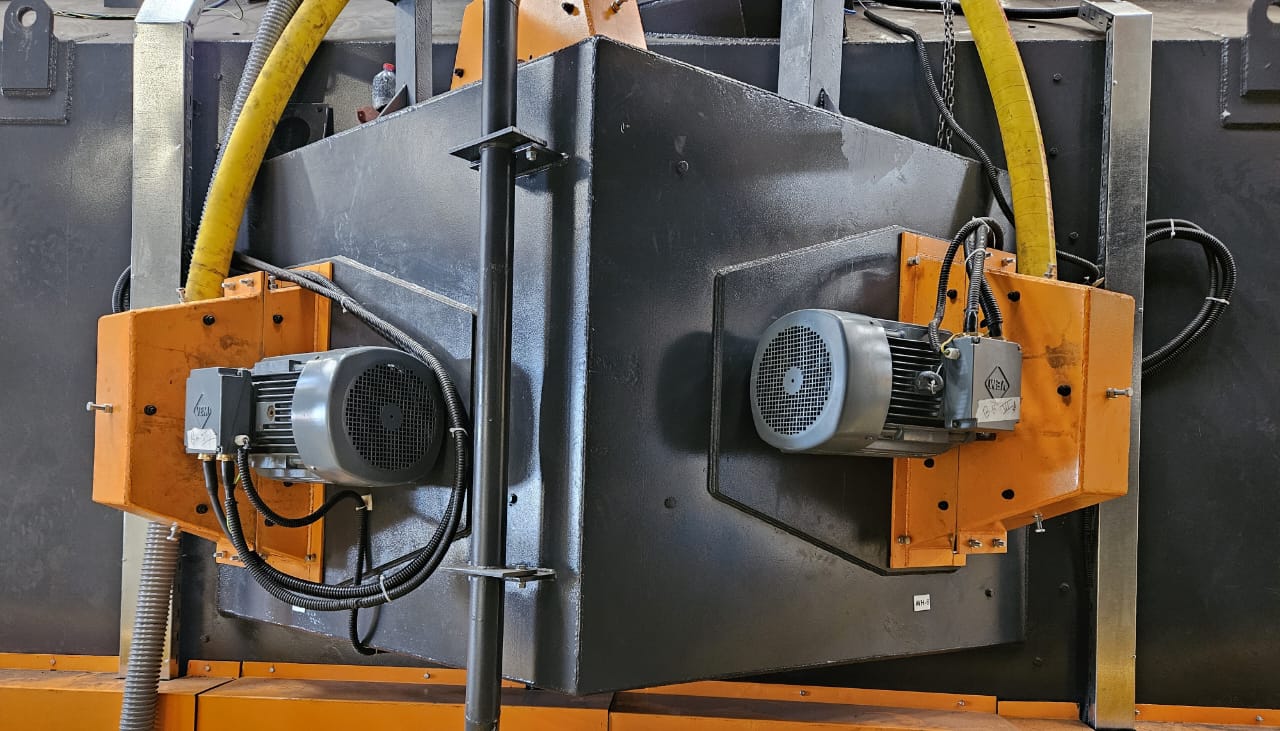

Shot Blast Wheel

Blast wheel shot blasting is the most economical method among the current surface cleaning methods, as well as the one that minimizes environmental impact. This process is a highly effective solution for removing contamination on metal surface and to create a surface profile before coating .The shot blasting principle is based on the use of kinetic energy from the abrasive used when it impacts the surface of the piece, removing impurities. Instead of compressed air, the wheel blast cleaning systems utilize a rotating wheel to propel the steel abrasive. This method is very efficient since the centrifugal wheel needs very little power to run . The impellor wheel is positioned inside a wheel housing, and abrasive is fed into the wheel’s center called the control cage.

Inside the impellor wheel, there are multiple blades. The abrasive travels along these blades from the control cage. Abrasive is then propelled in an arc at the product in a pattern called the blast pattern. The performance of the equipment depends on the quality, quantity, speed and direction of the abrasive . The wheel is the most important part of the machine, which has direct influence on the effectiveness of the blasting, the surface profile generated, the production costs and the profitability of the process. Shot blasting machines are designed with multiple wheels located suitably in such a way that the abrasive can cover the whole surface of the items to be shot blasted. The design is finalized based on the shape and size of the items to be cleaned apart from the targeted speed of blasting